Research

We aim to understand a wide range of fast dynamical processes in materials at the most fundamental level accessible. We specialise in producing high quality experimental data and developing cutting-edge and innovative techniques for understanding ultra-fast phenomena, including developing optical diagnostics and using high speed photography.

We work closely with our industrial partners and the UK Government, actively participate in a wide variety of research projects, and are always happy to discuss possible future research. Our wide range of experience allows us to offer practical advice on ways to obtain data on fast processes. We can perform a wide range of research in-house, but can usually put you in touch with other experts if we cannot.

Fracture and shock physics research has been on-going in the group since the late 1940's. This page highlights research topics which are under active investigation (or have been in the last few years), and further information about the group’s longer-term history and interests can be found here. The group often undertakes smaller projects around similar themes and retains and maintains the equipment and facilities to conduct such investigations.

Energetic Materials

Energetic materials cover a wide range of substances capable of releasing large amount of chemical energy quickly, and include propellants, pyrotechnics and explosives. Understanding the properties and mechanisms that control the behaviour of these materials is a substantial physical challenge, requiring a detailed understanding of the physical properties of the material. These properties can then be linked together using various theoretical techniques, such as the polymer Group Interaction Model (GIM) framework.

The group has a long history in studying the characteristics of energetic materials, dating back to the late 1940’s. Today we focus on applying modern methods to develop a much more complete understanding of the fundamental behaviour. A particular focus is on developing and instrumenting small scale experiments which can be used to provide fundamental insights enabling accurate models to be constructed, to understand larger scale response.

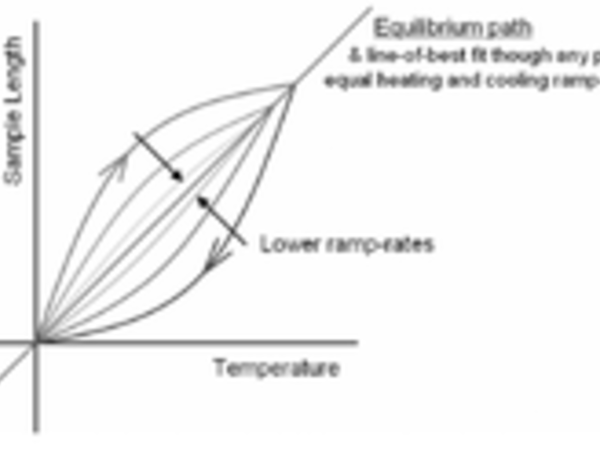

We use a variety of techniques to characterise the underlying physical properties of materials. These include thermal expansion (using direct and optical interferometric methods), heat capacity (using differential scanning calorimetry), thermal conductivity and differential mechanical analysis. Together, these can be combined to study the underlying thermodynamics and statistical mechanics of the materials.

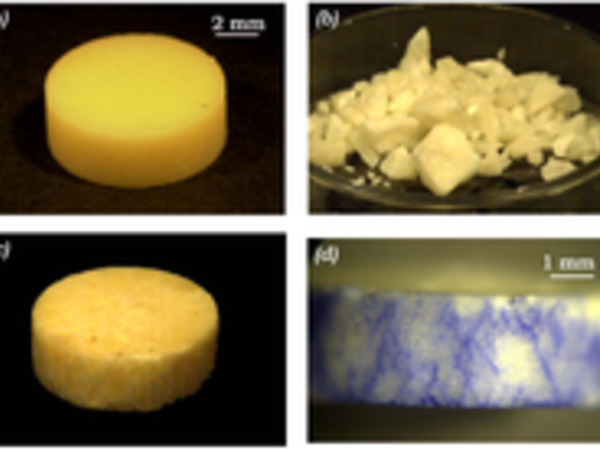

We characterise the structures of complex energetic materials using various forms of microscopy and non-invasive 3-dimensional imaging techniques, such as X-ray Computed Tomography. We have several ongoing projects to characterise the adhesive interaction between different materials, and the corresponding effect this has on the ultimate strength on the material.

Damage in energetic materials is a particularly important area. Damage can lead to an increased likelihood of energetic initiation, so understanding damage in detail is an important element of the explosive safety. We have several ongoing projects which include introducing controlled amounts of damage into energetic materials (propellants, PBXs) and studying the changes in both physical and energetic properties, as described in the papers below.

Novel fabrication methods for energetic materials are of particular interest. For example, we have recently been involved in a project to develop screen printable pyrotechnic inks, to reduce lead usage within the mining industry.

Granular and geological materials

In the past two decades research in this area has many different materials including fully dense and porous rock, sands and soils, concrete, ceramics, pressed metal powders, metallic and polymer foams, and porous energetic materials. Much of this research involved measuring the response of these materials to quasi-static, dynamic and shock loading – using both nominally one-dimensional methods, as well as more complex geometries. Experiments have included the use of high speed photography to observe crack growth, fragment size analysis and fractography of the samples post-experiment.

The group is also interested in wave propagation in granular materials. The non-linear mechanical nature of grain contacts results in granular materials having significantly lower sound speeds compared to fully dense materials. This phenomenon has been investigated through sound speed measurements and high speed photography on real granular materials, like sand, and idealised systems such as chains of identical spheres.

Research has also looked at ballistic penetration into sand and concrete. In these experiments a flash X-ray system and digital image correlation was used to observe flow within the material during penetration.

Fibre Composites

Similarly to granular and geological materials, the properties of composites (e.g. GFRP and CFRP) depend on both the material properties of constituent elements, and their micro-, meso- and macro-scale structure. Probing the rate-dependent behaviour of such materials poses a particular challenge, as each individual component has its own rate dependences. Again, here understanding damage and degradation of these materials is of particular interest, and there’s a critical need to understand through-life performance.

Polymers

Polymers are a diverse family of materials with a wide range of applications in industries such as automotive, medical, defence and others. It is therefore important to understand their properties under a range of conditions.

In our group, we utilise our experimental capabilities to measure polymer properties. We can measure heat capacity in the temperature range 25-450 K and thermal expansion in the range 120-420 K. In terms of mechanical properties, we have measuring capabilities from quasistatic rates in the Instron, moderate rates in the DMA machine and high rates in the Hopkinson bar, impact tests, and ultrasonic and shock measurements.

We use our datasets to populate models for structure-property relations of polymers. In particular, the group has been working with Group Interaction Modelling, which is a framework that uses the chemical structure and configuration of the polymer chain to predict its bulk properties.

Metals

Understanding the mechanical and microstructural properties of metals is of great importance both in terms of the fundamental science involved and also in the application of this science owing to the high level of usage of metallic objects. A variety of models are available to predict the response of metals in various situations, with varying levels of physical basis. An important area which is not well understood is how these different models can be applied to predict material behaviour with increasing strain rate, leading onto failure, particularly as a function of the initial condition of the material. This knowledge of the original state is known as path or history dependence.

Completely characterizing path dependence requires a wide range of experimental techniques. Most notable are those at medium to high rates, such as Split Hopkinson Pressure Bar experiments, where effects caused by sample inertia need to be discerned from the true material response.

Numerical simulation is key to applying and testing the models which are used to predict this behaviour. The research carried out in this group aims to aid in the parameterisation of these models, and to develop them to better describe the experimentally observed nature of path dependence.

Other areas of interest

In recent years we have worked on ceramic armour systems, a “space penetrator” (designed to contain scientific apparatus able to withstand impact into Europa, one of the moons of Jupiter), reactive metals, and much more besides.

Our expertise is focussed on experimental methods – both high strain rate processes and accompanying thermo- and mechanical materials characterisation; applications of those experiments are very broad, and lead us to new and evolving interests in a wide range of novel functional and structural materials